Copper Cathode

Copper cathode is a highly refined form of copper, typically with a purity level of 99.99%. It is produced through electrolytic refining, where impure copper is dissolved in an electrolyte solution, and pure copper is deposited onto cathodes. These cathodes are harvested, washed, and melted to remove any remaining impurities, resulting in a high-purity copper product.

Physical and Chemical Properties

- Purity: 99.99% Copper

- Form: Rectangular plates, typically weighing between 50 to 80 kg each

- Color: Reddish-brown

- Density: 8.96 g/cm³

- Conductivity: Excellent electrical and thermal conductivity

Production Process

The production of copper cathodes involves several steps:

- Mining and Crushing: Copper ores are mined and crushed into fine particles.

- Concentration: The ore is concentrated using froth flotation.

- Smelting: The concentrated ore is smelted to produce copper matte.

- Refining: The copper matte undergoes electrolytic refining. In this process, an electric current passes through an electrolyte solution, causing pure copper to deposit onto cathodes.

This process ensures that the final product, the copper cathode, is of extremely high purity and suitable for various industrial applications.

-

Scrap Products

Scrap ProductsUsed Rail Scrap

$0.00 Add to cart -

Scrap Products

Scrap ProductsAlluminium wire scrap

$0.00 Add to cart -

Scrap Products

Scrap ProductsCopper Cathodes

$0.00 Add to cart -

Scrap Products

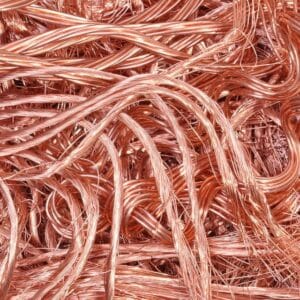

Scrap ProductsCopper Wire Scrap

$0.00 Add to cart -

Scrap Products

Scrap ProductsUsed Scrap Batteries

$0.00 Add to cart -

Scrap Products

Scrap ProductsUCB bailed aluminium beverage cans

$0.00 Add to cart -

Scrap Products

Scrap ProductsIntel cpu processors

$0.00 Add to cart