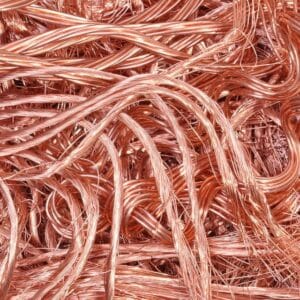

Alluminium wire scrap

Aluminium wire scrap is a vital commodity in the recycling industry, representing an important source of raw material for the production of new aluminium products. With growing environmental concerns and the increasing demand for sustainable resources, the recycling of aluminium has become a key focus for industries worldwide. The demand for aluminium wire scrap, specifically, has surged due to its ease of recycling, high-quality yield, and the metal’s growing importance in sectors such as construction, automotive, aerospace, and electronics.This comprehensive description will explore the various aspects of aluminium wire scrap, including its characteristics, sources, recycling process, applications, benefits, and its role in the global aluminium market. It will also highlight the growing importance of aluminium recycling in contributing to a circular economy and reducing the environmental footprint of aluminium production.

1. What is Aluminium Wire Scrap?

Aluminium wire scrap refers to pieces of aluminium wire that have been discarded or removed from use, typically due to being either damaged or obsolete. The wire scrap may come in a variety of forms, including wires of various sizes, lengths, and grades, often collected from industrial or residential sources. Aluminium wire scrap can come from several different applications, such as electrical wiring, cables, and other electrical components. Due to aluminium’s excellent conductivity and corrosion resistance, it is commonly used for manufacturing electrical wires, and as such, aluminium wire scrap can often be found in discarded cables and wires from electronic devices, machinery, and construction debris.The main appeal of aluminium wire scrap lies in its high recyclability. Aluminium is one of the most easily recycled metals, and a significant percentage of new aluminium products are produced from recycled scrap. Aluminium wire scrap is a valuable resource in the recycling process, as it can be melted down and reformed into new aluminium products, including new wires, cables, and other structural components.

2. The Sources of Aluminium Wire Scrap

Aluminium wire scrap can come from a variety of sources. It can be generated from both industrial and consumer sectors, as well as through the disposal and demolition of infrastructure. Key sources include:

2.1 Residential and Commercial Electronics

Aluminium wire scrap often arises from the disposal of electronic appliances such as televisions, air conditioners, refrigerators, and microwave ovens. These items often contain aluminium components such as wiring, which, when discarded, contribute to the overall volume of aluminium scrap.

2.2 Electrical Infrastructure

Aluminium is widely used in power transmission and distribution cables due to its light weight and excellent conductivity. Over time, as cables age or are replaced with newer technology, they become a source of aluminium wire scrap. Power lines, telecommunications cables, and underground wiring are common sources of scrap.

2.3 Automotive and Aerospace Industries

Both the automotive and aerospace industries use aluminium for wiring and other lightweight components. When vehicles and airplanes are decommissioned, the wiring used within them can be removed, generating aluminium wire scrap. This type of scrap is particularly valuable due to its quality and composition, which may be more suited for recycling.

2.4 Industrial Manufacturing

Factories that manufacture electrical equipment, machinery, and components frequently discard aluminium wire and cables during production. These wires may have been damaged or cut to the wrong specifications during manufacturing processes.

2.5 Construction and Demolition Projects

Construction and demolition projects can also produce large amounts of aluminium scrap. Aluminium wiring and cabling from old buildings, infrastructure, and machinery can be recovered and used as a source of wire scrap for recycling.

3. The Aluminium Wire Scrap Recycling Process

Recycling aluminium wire scrap is a straightforward process that involves several key stages, from collection and sorting to melting and refining. The recycling of aluminium is highly efficient and involves less energy consumption than producing aluminium from raw bauxite. The process is as follows:

3.1 Collection and Sorting

The first step in recycling aluminium wire scrap is its collection. This can take place at industrial sites, recycling centers, or even through curbside pick-up services. The collected scrap is then sorted based on its type and quality. Sorting ensures that only aluminium wire is processed, while non-aluminium materials such as plastics, rubber, or copper are removed.

3.2 Shredding and Cleaning

After sorting, the aluminium wire scrap is often shredded into smaller pieces. This step helps to reduce the size of the wire, making it easier to process in subsequent stages. Shredding also facilitates the removal of insulation and contaminants such as coatings, oil, and dirt. Cleaning may involve mechanical methods or chemical treatments to remove any unwanted substances.

3.3 Melting

Once the aluminium wire scrap has been shredded and cleaned, it is melted in a furnace. Melting aluminium requires significant heat, typically around 660°C (1220°F), although this temperature can vary based on the specific alloy of aluminium being recycled. The scrap aluminium is placed in the furnace, where it melts and forms a liquid metal.

3.4 Refining and Alloying

The molten aluminium is then refined to remove any remaining impurities. This may involve the addition of certain chemicals or the use of electrolysis to remove unwanted metals and materials. If the wire scrap is intended for a specific application, it may be alloyed with other metals like copper or magnesium to achieve the desired properties for use in manufacturing.

3.5 Casting

After the aluminium has been refined, it is cast into ingots or billets. These cast forms are easier to handle, transport, and store. These ingots or billets can later be used in the production of new aluminium products, including fresh aluminium wire or cable.

3.6 Forming and Manufacturing

The final step in the recycling process involves the use of the cast aluminium to produce new products. For aluminium wire scrap, the ingots or billets are rolled or drawn into wire of various gauges or sizes depending on the specific needs of the market. This wire can be used to make new electrical cables, wires, and other components.

4. Key Characteristics of Aluminium Wire Scrap

Aluminium wire scrap possesses several key characteristics that make it an attractive option for recycling:

4.1 Lightweight and Flexible

Aluminium is known for its lightweight nature, which makes it a highly desirable material for applications that require flexibility and ease of handling. In addition to its low weight, aluminium wire is often flexible, allowing it to be easily bent and shaped during manufacturing processes.

4.2 Excellent Conductivity

Aluminium wire scrap is valuable for its electrical conductivity, which is second only to copper among metals commonly used for electrical components. This makes it ideal for recycling into new electrical cables and wires, which require high conductivity for efficient transmission of electricity.

4.3 Corrosion Resistance

One of the standout properties of aluminium is its resistance to corrosion, particularly when exposed to moisture. This property makes it ideal for use in outdoor and exposed applications, such as power lines and electrical infrastructure. Even after years of use, aluminium wire scrap can still be recycled into high-quality, corrosion-resistant wire products.

4.4 Non-Toxic and Environmentally Friendly

Unlike other metals, aluminium is non-toxic and does not release harmful substances during the recycling process. As a result, aluminium wire scrap recycling is considered a safe and environmentally friendly process. The low environmental impact of recycling aluminium also contributes to its growing importance in sustainable manufacturing.

5. Applications of Aluminium Wire Scrap

Recycled aluminium wire scrap has a wide range of applications across numerous industries. The recycling process ensures that the final product retains the essential properties of the original material, making it suitable for use in high-performance applications.

5.1 Electrical Wiring and Cables

One of the primary uses of aluminium wire scrap is in the production of new electrical wiring and cables. Due to its excellent conductivity, aluminium is widely used in electrical power transmission, telecommunications cables, and various other electrical components. The high-quality wire produced from recycled scrap can be used in residential, commercial, and industrial applications, including power distribution networks and electronic devices.

5.2 Automotive Industry

Aluminium wire scrap is used in the automotive industry, where lightweight materials are critical for improving fuel efficiency and reducing emissions. The scrap can be recycled into wire components for electrical systems, connectors, and battery cables in electric vehicles (EVs) and conventional cars alike.

5.3 Construction and Building

In construction, aluminium wire scrap is recycled into various products, such as cables used in lighting systems, HVAC (heating, ventilation, and air conditioning) systems, and electrical installations within buildings. Aluminium’s resistance to corrosion makes it an ideal choice for use in structures that require durable and long-lasting materials.

5.4 Aerospace and Defense

In aerospace and defense, aluminium is widely used for its strength-to-weight ratio and its ability to withstand extreme conditions. Aluminium wire scrap is recycled into components used in aircraft wiring, communication systems, and military electronics. Its lightweight properties make it an ideal choice for reducing the weight of aircraft and spacecraft.

5.5 Consumer Electronics

Recycled aluminium wire scrap is also used in the production of wires and cables for consumer electronics such as smartphones, computers, televisions, and home appliances. Aluminium’s good conductivity and flexibility make it a popular choice in these applications.

5.6 Renewable Energy

Aluminium wire scrap is becoming increasingly important in the renewable energy sector. Recycled aluminium is used in solar panels, wind turbines, and other green technologies, where it contributes to the efficient transmission of energy and supports the shift toward cleaner energy sources.

6. Advantages of Recycling Aluminium Wire Scrap

The recycling of aluminium wire scrap offers numerous environmental and economic advantages, making it a highly attractive option for industries and governments seeking to promote sustainability.

6.1 Energy Efficiency

Recycling aluminium requires significantly less energy compared to the production of new aluminium from raw bauxite ore. The energy savings from recycling aluminium wire scrap can be as high as 95%, which greatly reduces the environmental impact of aluminium production.

6.2 Reduction of Carbon Emissions

The reduced energy consumption associated with recycling aluminium leads to a significant reduction in greenhouse gas emissions. This is especially important in the context of climate change, as recycling helps to lower the overall carbon footprint of aluminium production.

6.3 Conservation of Natural Resources

Aluminium wire scrap recycling conserves natural resources by reducing the need for bauxite mining. This helps preserve ecosystems and

Aluminum Wire Scrap

Specifications High Performance Products broad-spectrum 6063 aluminium extrusion scrap for sale

- Item : aluminium scrap

2. Easy control and operation

3. Fast melting

4. Discontinuous melting with scrap

5. High efficiency

6. Stable working structure

7. Usage : It mainly used for drawing back non-ferrous metal typical material is :wasted copper, aluminum, cable, aluminum stuff, wasted auto spare part, non-ferrous metal scrap, dross for printing, broken glass contains non-ferroous, electronic waste etc.

8.This aluminum can press that was pressed with our company’s pressing machine.We may change quantities and prices from time to time, so please inquire to confirm.

9.We respond to quantity and price inquiries.We also carry other merchandise. Please inquire if you are interested. Item Quality standard Si 0.2-0.6% Fe 0.35% Cu 0.1% Mn 0.1% Mg 0.45-0.9% Cr 0.1% Zn 0.1%